December, 1984, The Atlantic

December, 1984, The Atlantic

"Technology is moving at a much faster clip than our laws can keep up with"

~ Deborah Hersman

This Should not have Happened

September, 1938, Eww

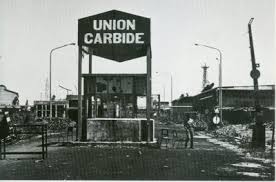

Union Carbide moved to Bhopal in 1969. It was an American based company. They have had problems before with safety and keeping things updated and regulated. Three years before the major disaster a smaller leak occured with phosgene gas that killed three workers. This caused a big lawsuit and a whole section in the factory to be shut down.

Before the leak, inspectors came to inspect the facility but they were very lax and the infrastructure wasn't important. It turns out there were over six major safety issues with equipment. The section that the leak occurred was section C. It happened from tank cover gave way. Designing flaws, operating errors and economy measures were all major reasons this happened.

Date accesed February 4, 2020, Bhopal Aftermath

Inexpierience in the Workplace

"Due to poor maintenace, many pieces of plant equipment were missing at the time of the accident."

~ Historytoday.com

Date accessed December 13, 2019, Images All Disaster Msimages

Other than the problems with the equipment in the plant, that night they had no experienced supervisors on shift. There was only one safety officer on duty that was in charge of the whole plant that night. The other operators were uneducated about how to correctly work the valves and switches. This was a preposterous mistake.

This concludes that this whole disaster was 100% Union Carbide's fault. They had been warned countless times and it was just a matter of time before this would happen. After the leak, law enforcement went into the factory and a reported 61 hazardous things were in the plant. This later lead to Union Carbide getting shut down and it is still abandoned to this day.

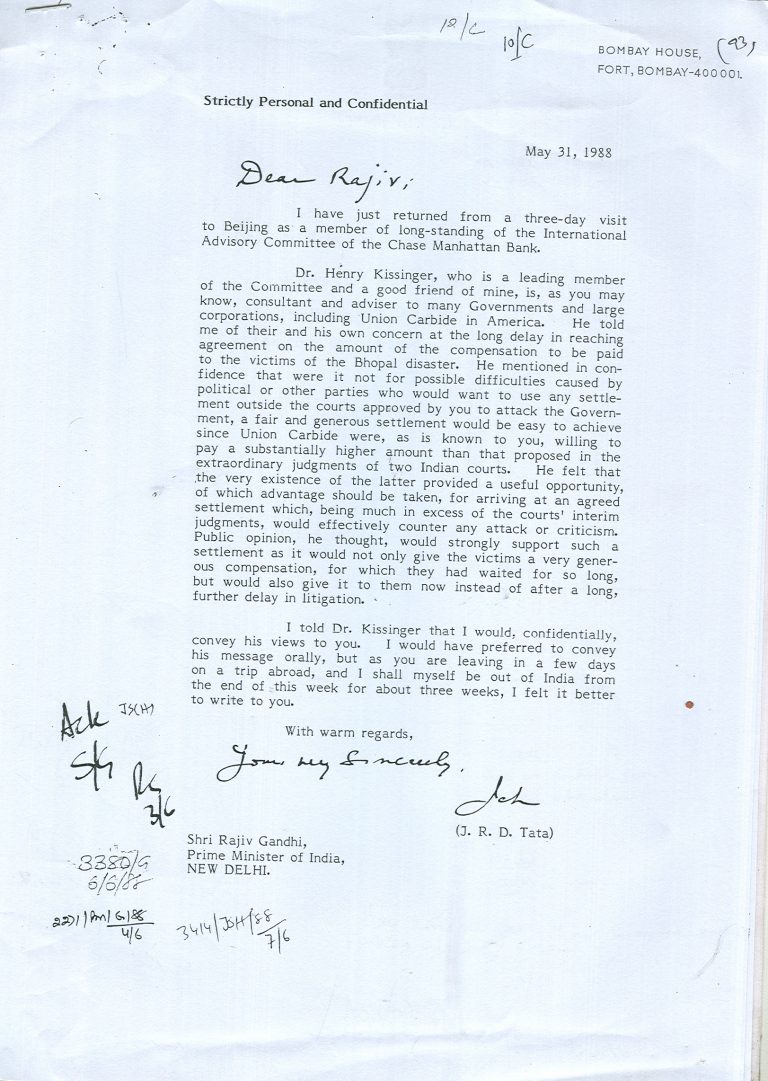

May 31, 1988, The Print